Manufacturing for Business Central

Meets your manufacturing needs in packaging, assembly, semi-process and bulk production

The production operation can be complex and impact on productivity when manufacturers want to provide a personalized and competitive offering to the supply chain.

Fully integrated with Microsoft Dynamics 365 Business Central, Prodware Manufacturing helps by combining market-leading ERP software with tailored features you need in this fast-moving industry.

BENEFITS – Prodware Manufacturing for Business Central

Optimized Manufacturing Operations

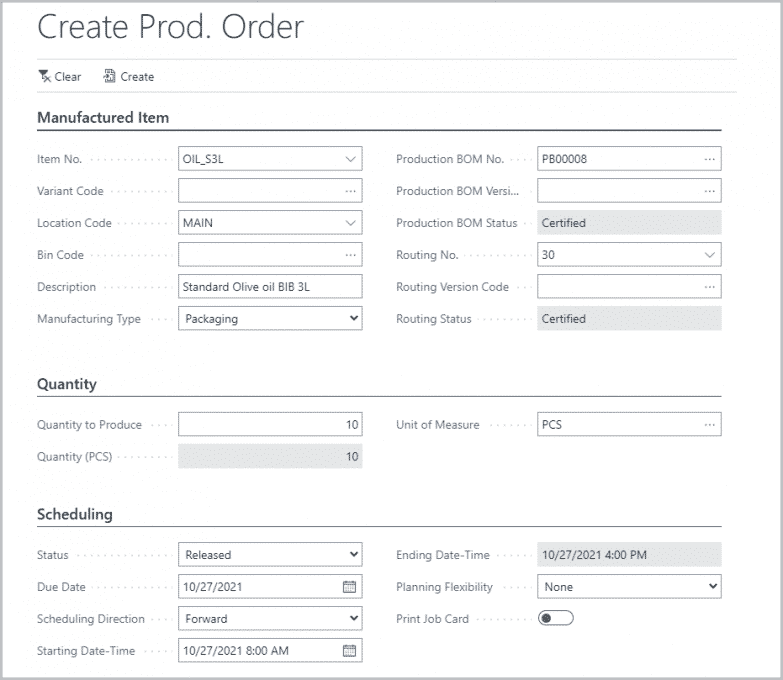

Simplified Processes for Production Order, BOM, and Routing Creation

Enhanced Inventory Tracking

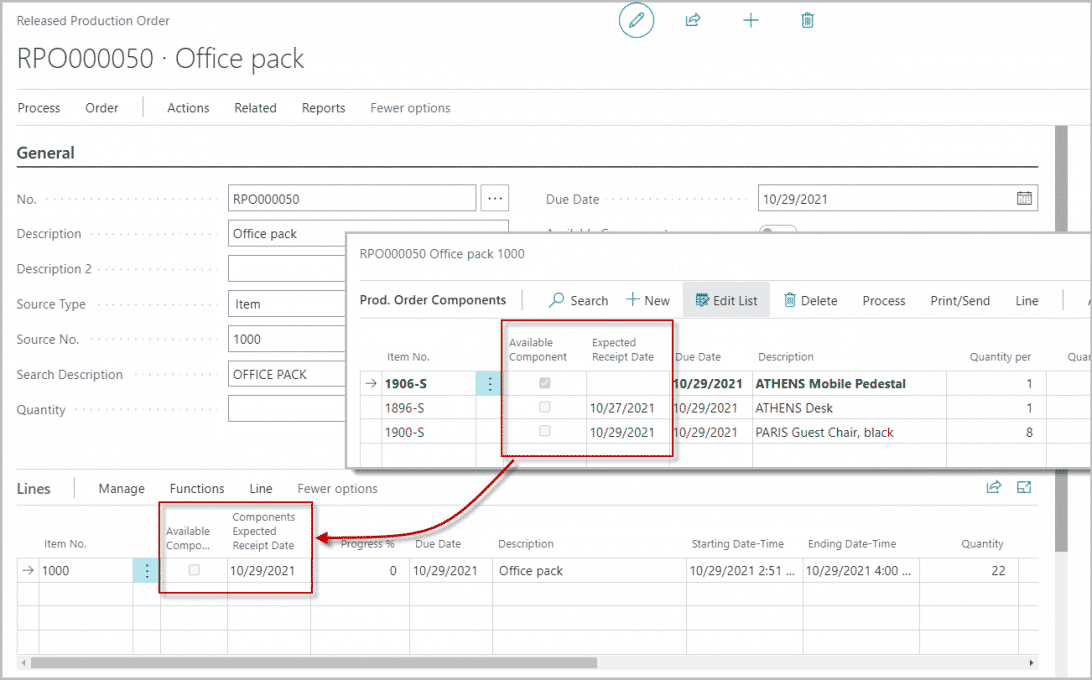

Increased Visibility into Location of Production Order Components

Streamlined Capacity Management

Quicker Machine and Work Center Capacity Visibility

Improved Quality Assurance

Quality Management, Regulation, and Compliance Processes

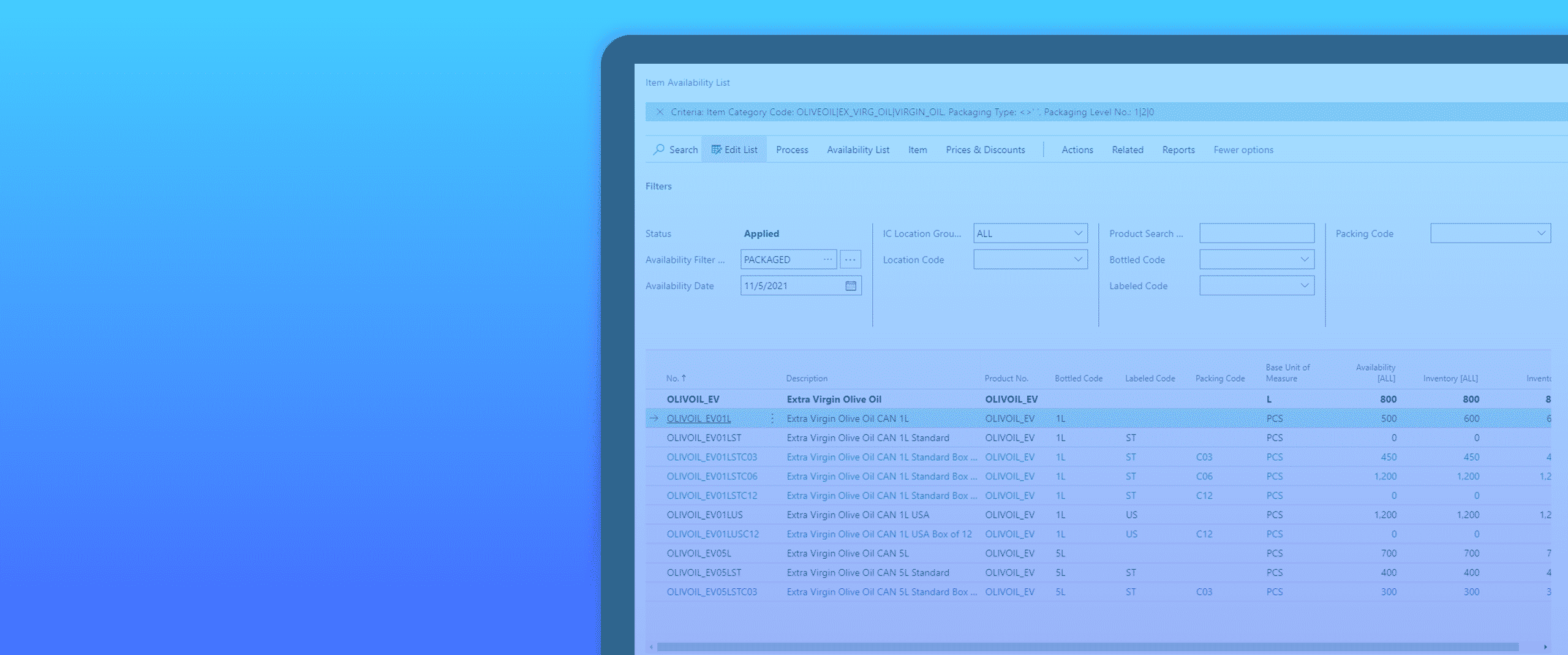

Advanced Warehouse Management

Boosted Processes and Item Availability

Shop Floor Efficiency

More Detail and Time-Saving on Job Card Printing

Packaging Customization

Increased Flexibility on Packaging Options

Precise Batch Control

Enhanced Batch Management for Formulae and BOM Lot Sizes

Personalized Customer Engagement

Customer-Centric Approach with Tailored Offers

Supplier Collaboration

Increased Flexibility and Controls with Suppliers

Reliable and Adaptable Data

Data Accuracy and Flexibility

Seamless Demand Planning

Easier Integration with Demand Forecasting

CAPABILITIES – Prodware Manufacturing for Business Central

Additional functionality has been integrated with Dynamics 365 Business Central in areas such as:

Standard manufacturing enhancements

This solution expands on the standard Routing features with the ability to copy Routing, get quick access to change log and attach documents to a routing and routing version. The same applies for improvements in BOM (whatever the type e.g. production, packaging etc.). When a user wants to search for key information for a production order (progress, components, documents), this can often take several clicks and even just show one; the solution rectifies this with quick access enhancements.

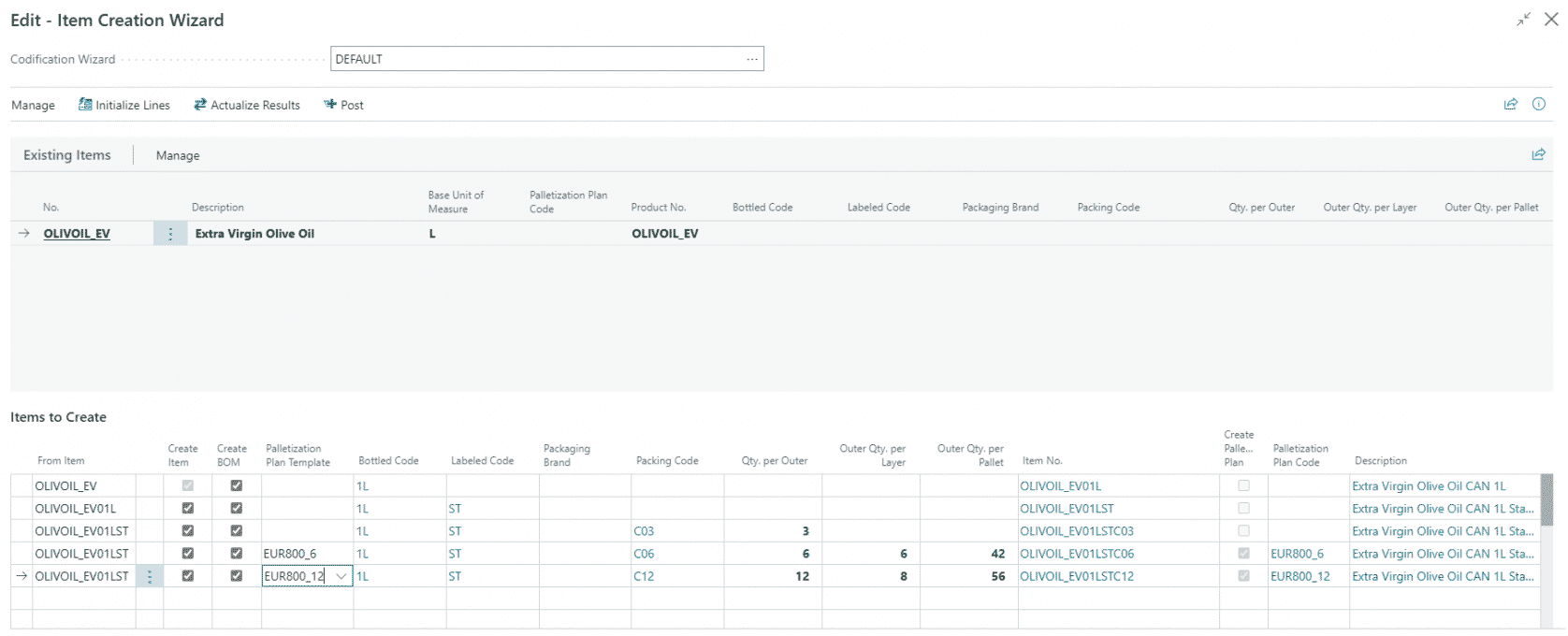

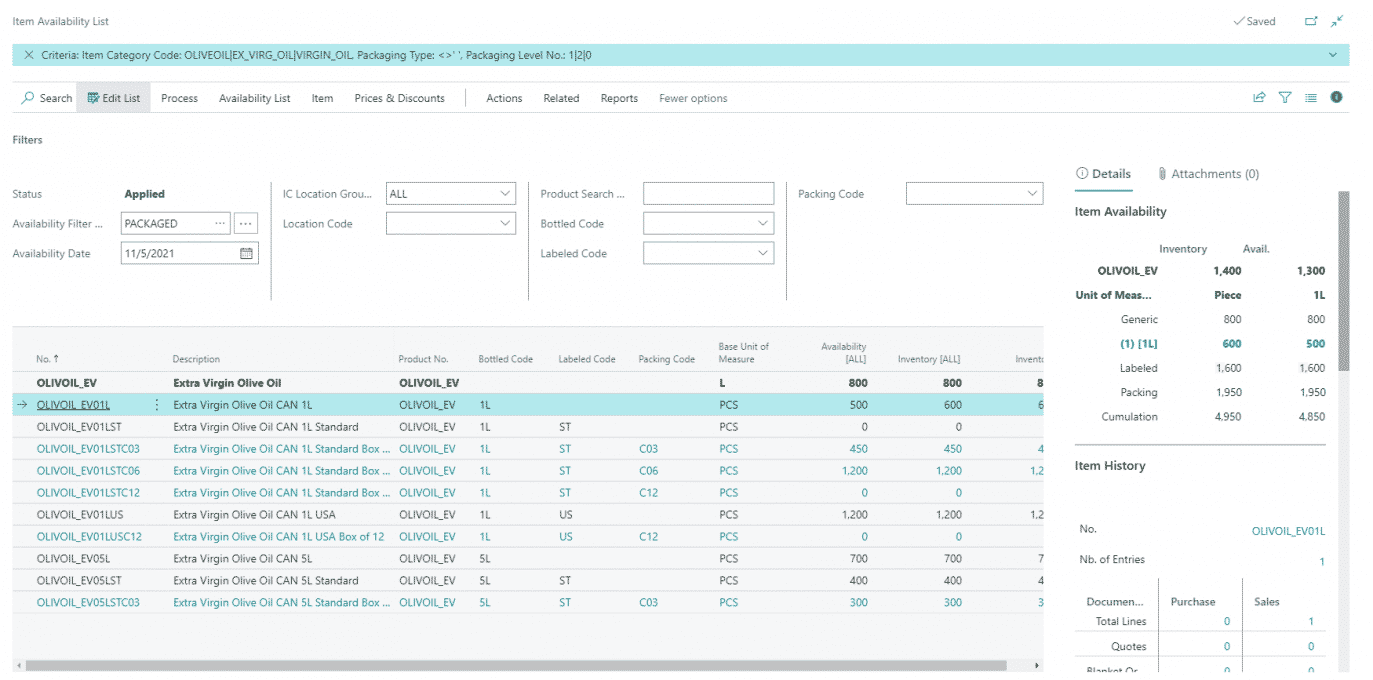

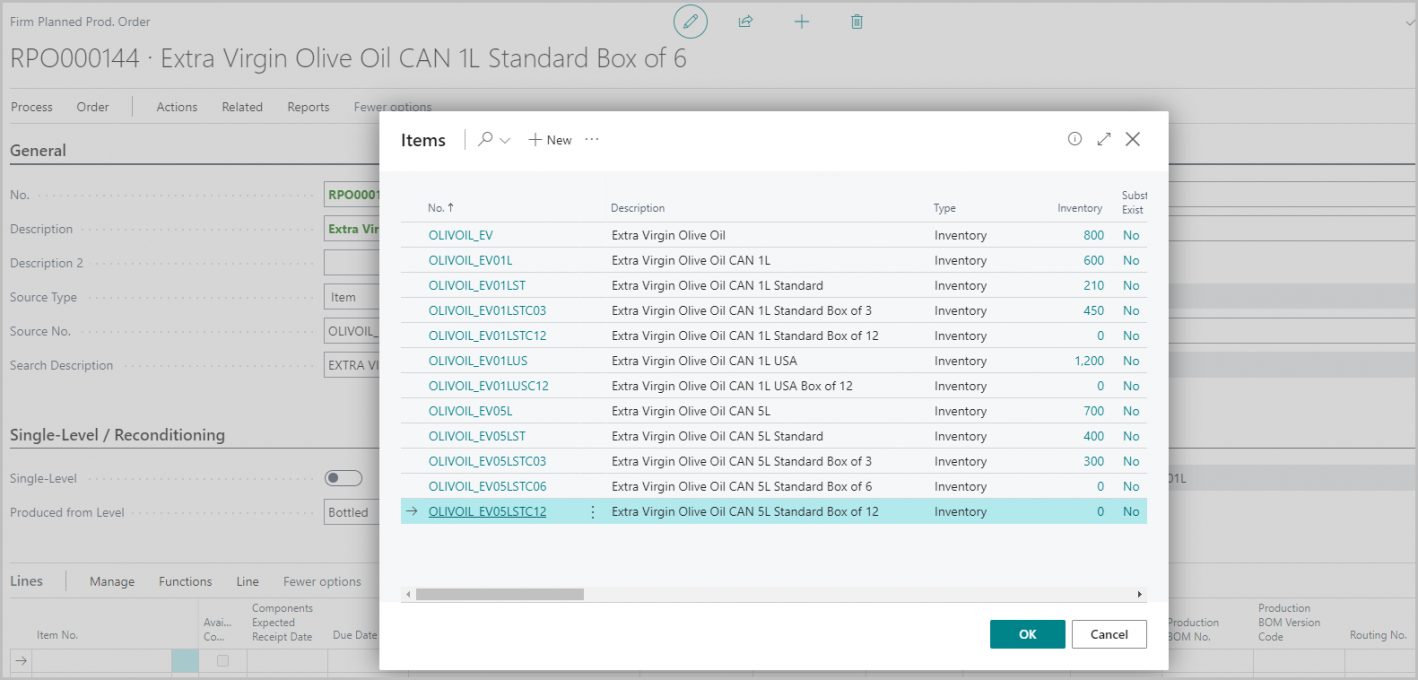

Packaging management

We’ve added more levels to Packaging Management functionality for you to create and manage several levels of semi-finished items linked to a product, this can take into account different ways you pack and market your product. The Item Generator is a wizard that allows you to set up item code, BOM, routing, weight and volume etc. at the time of creating your item, saving time. The solution includes an improved Palletization Plan Template so that you can add default values related to packaging management.

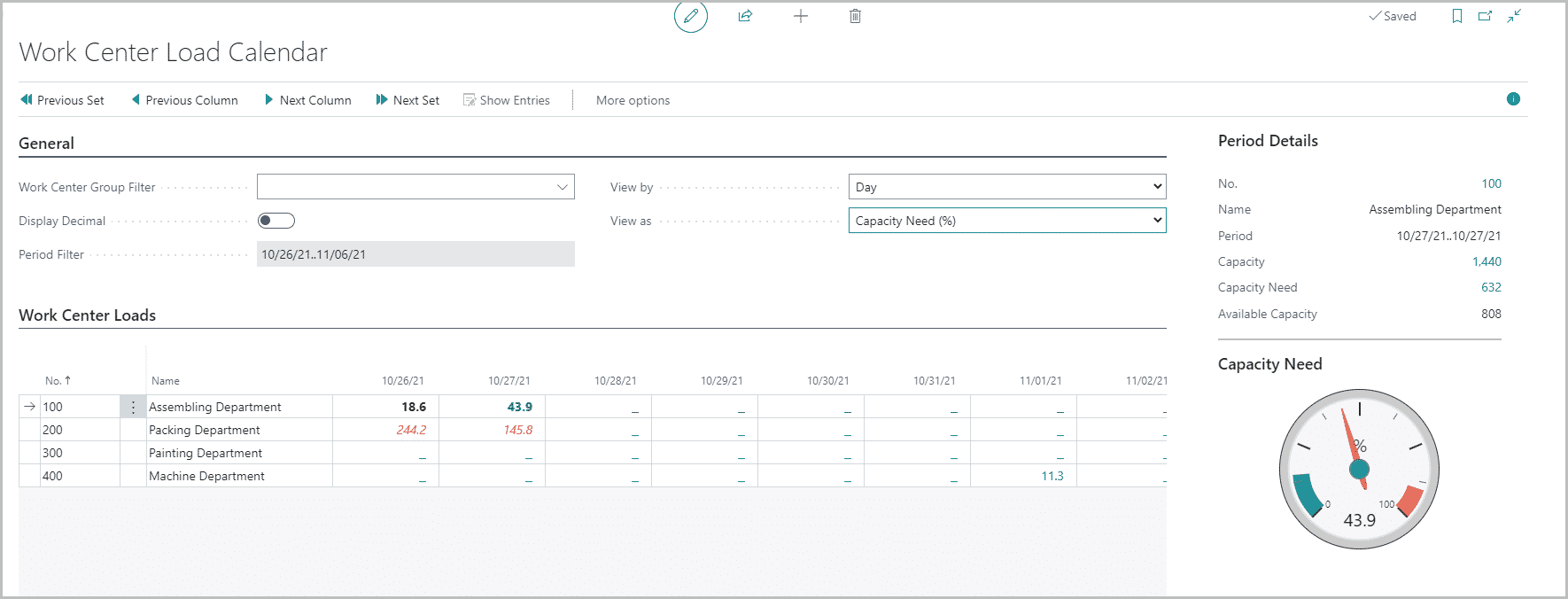

Production load planning

The two Load Calendar dashboards display the production load on a fixed horizon. The load from production orders can be viewed by period, either on machine centers or work centers. It calculates the remaining capacity, load or availability of a machine center or a work center, over a defined period of time.

Integrated quality, regulations and compliance management

Including automated quality controls in production and warehouse, non-conformities, complaints management and analysis. Classification, Labelling and Packaging (CLP) Regulation are introduced in Business Central. Users can assign GHS Symbol, H and P Phrases to items.

Batch management

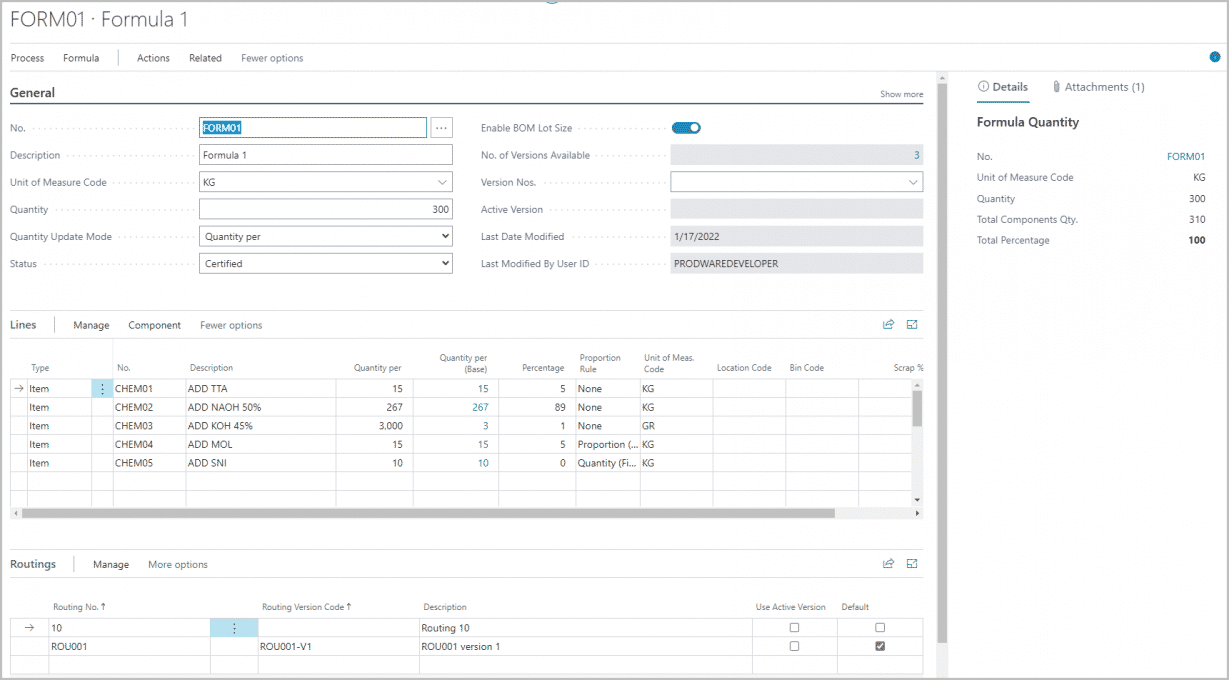

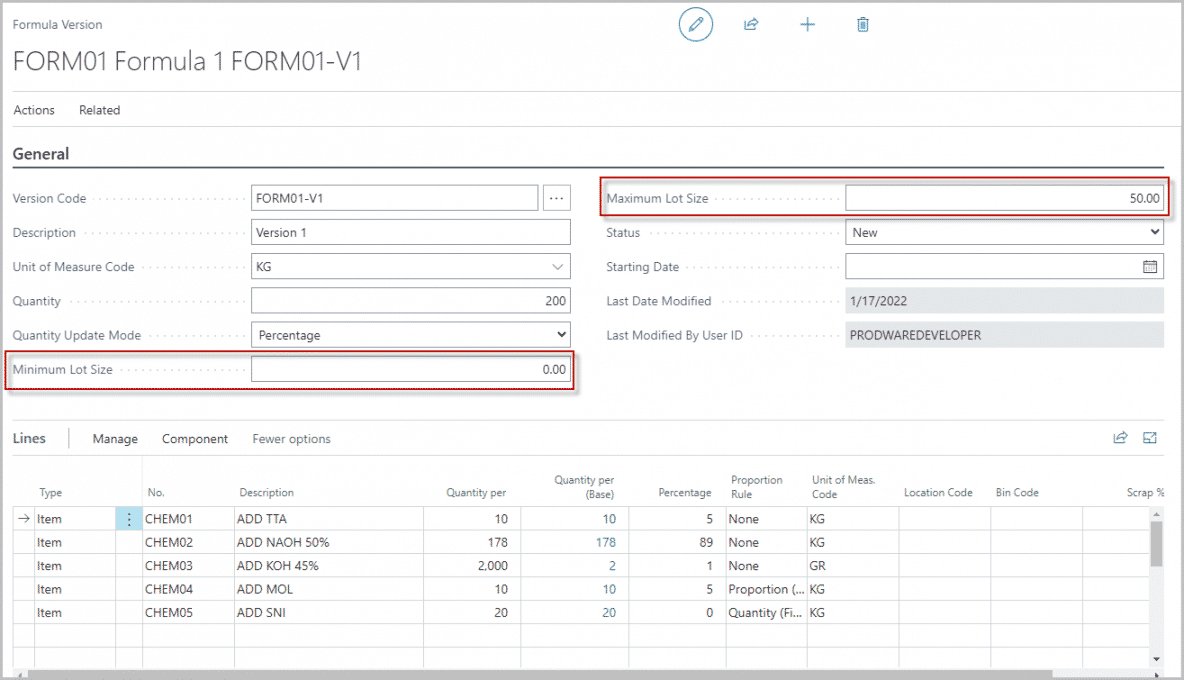

In Formula Management, a new type of BOM (formula) allows the user to build the BOM lines by using component percentages, manage the notion of fixed or proportional quantity on each line and attach a routing to a formula.

In BOM Lot Size, the user can attach a minimum and maximum quantity to versions of a BOM. When a production order is created, the BOM version to use will depend on the quantity to produce.

If you use batch management in a production order, Batch Composition allows you to automatically split the desired quantity to produce into several production orders so that the size of each batch is maintained.

The Uniqueness of Lot feature allows the business to prohibit the use of several lot numbers of a component within a single production order.

Improved warehouse management

Warehouse Management functionality extends existing Business Central warehouse management features to easily handle pallet management, bin management, packaging and also printing and reading of labels.

With Move Bin content feature users can easily move the entire contents of a Bin to another Bin, rather than item by item.

We have enhanced physical inventory processes with synchronized physical inventory and item ledger updates with the help of automation.

The SSCC Management functionality means users can manage SSCC numbers in the shipment process of Business Central (SSCC number generation, assign SSCC number to shipment documents and print labels with SSCC information).

Sales and procurement productivity, best practice and flexibility

Commercial enhancements include pricing levels and discounts, trading structures, shipping status and free product items to offer a personalized service to your customers.

Purchasing teams have additional flexibility in supplier agreements, tender management, shipping management, and controls in place for purchase restriction and commitment.

FEATURES – Prodware Manufacturing for Business Central

In addition to the Prodware Distribution solution, the following Dynamics 365 Business Central accelerators are included in the Prodware Manufacturing solution.

Quality Management

Quality Control functionality helps manufacturing and distribution companies measure and manage quality compliance throughout their production and inventory processes. It manages central product specifications, quality orders and shipments.

Complaints Management helps organizations to register and manage complaints from customers, suppliers and employees. They follow best practice with workflows, prioritization, corrective action suggestion, follow-ups and related documentation. The escalation framework for non-conformity procedures helps when internal due process is not followed.

Technical

Mandatory Fields functionality: Seven areas in Dynamics can be selected and made mandatory fields – customer, vendor, General Ledger account, Items, Resource, Jobs and Fixed Assets.

Free Fields functionality: Organizations need to seek development if they require additional flexibility in adding fields to suit their business processes. With no development needed, the accelerator enables 14 fields to customize item, customer and vendor data which are then propagated to Sales and Purchase documents.

Warehouse Management

Do your finance, sales and warehouse teams have to make several steps when physical stock is updated for a location code, switch between systems in order to manage SSCC, have to manually update item ledger entries to reflect the change, or not know the number of pallets required for a shipment when putting together a sales order? The Warehouse Management accelerator for Microsoft Dynamics 365 Business Central helps extend existing inventory features and remove the need for double admin and switching between several processes and third-party systems.

Why choose Prodware?

As leaders in digital transformation, our approach as a trusted advisor for our clients helps you match leading technologies with business realities, to meet the challenges of your sector. We create sector-specific solutions to answer to your needs with best practice in mind.

Discover how Prodware Manufacturing for Dynamics 365 Business Central can transform the way you do business.